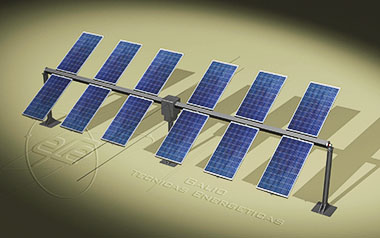

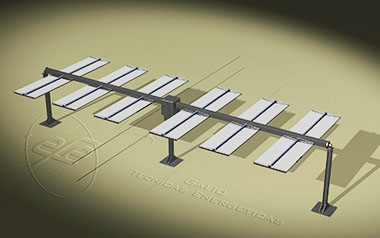

Galio E2S two axis ground tracker

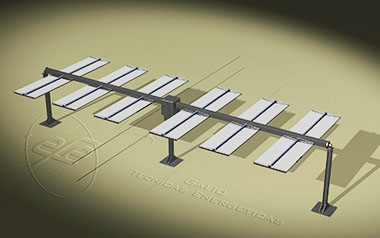

The Galio model E2S is the only two-axis tracker for industrial or buildings roofs.

Its low weight has been refined from its design to allow versatile use of this model, both as floor or roof use.

The optimization of the manufacturing layout of this tracker, and its sturdy design basis, means cheaper cost of manufacture to enable prices converge to parity pricing, and even beat it in regions of high solar radiation.

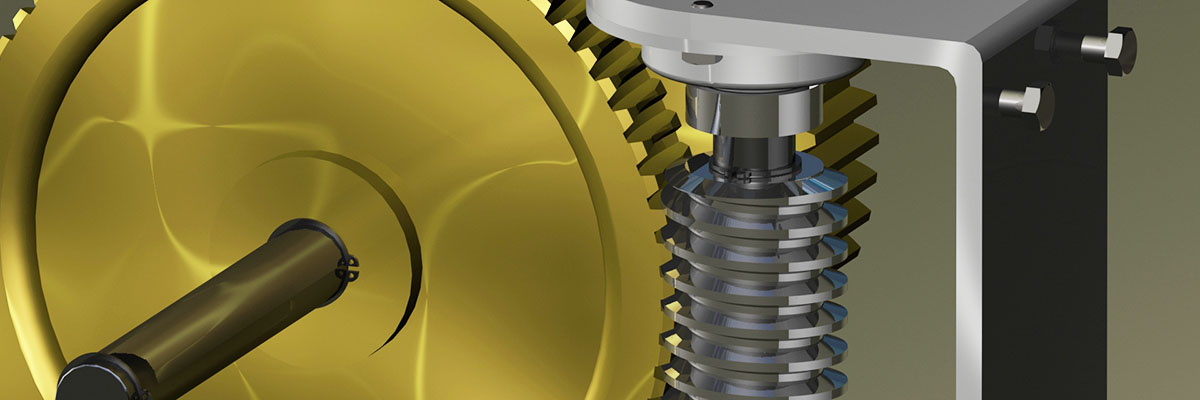

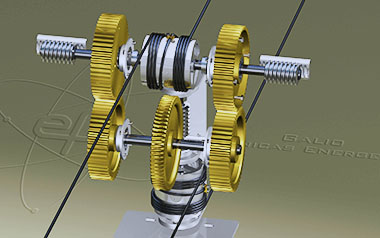

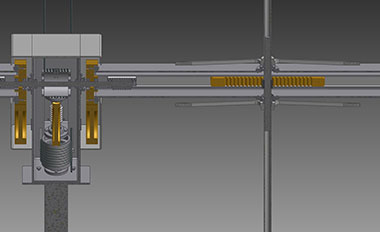

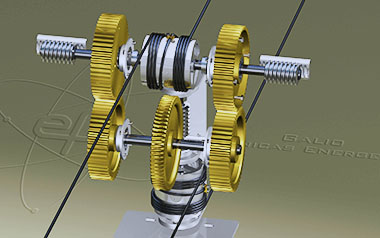

A drum (pull-pull) gives the rotation movement on the x axis (east-west) of the supporting beams of plates, with the zenith tracking the sun's altitude.

The axes of rotation are also symmetry axes, therefore canceling all external forces and loads .

The tracker has been designed to minimize its cost of manufacture and assembly on site, in order to promote generation costs below the rate parity.

The interior racks with three straight teeth sections and one section of helical teeth, transmit motion to six panels with carrier shafts spur gears.

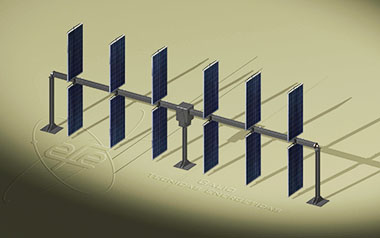

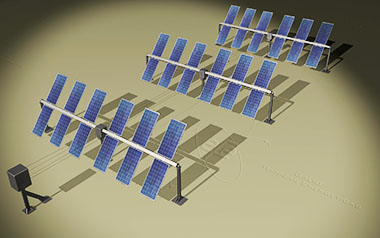

The rotation of the shafts allows turning upside-down the panels overnight to avoid dirt on the active surface.

Furthermore, this position is defense against high speed winds. It is designed to withstand hurricanes of 240 (km/hr) with the defense seeking at 120 (km/hr).

The turning ability, unique for these trackers, allows, automatic and overnight,search, for expose to rain the PV panels to wash them. Then turns to night position with an offset of 5 ° for rainwater percolating through the active surface of the PV panels, leading to dry.

A compact set allows two-axis tracking for a 12 PV pannels array. At the same time, their system of pull-pull drive, transmits the movement to 100 twin trackers. Thus, only two motors, allow the drive for 1200 PV panels.

The worm screw locks the system, isolating the exogenous forces that hit the mechanism, separating the drive motor from these loads.

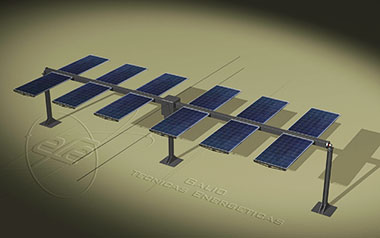

The torque transmission between different trackers, is done by steel cables, according to the pull-pull system.

This system gives the mechanism a lightness, reliability and low cost; wich provides advantage over others ground tracker manufacturers in the world, also being, the only two-axis roof tracker in the market to date.

Tracker drive mechanisms are internal and have been lubricated tribologicaly to avoid greasing over a lifespan of 40 years.

The trackers are associated in series, being driven by two motor heads at the beginning and end of the series . The transmission of movement is performed by the pull-pull action of the steel wires that are wound on drums located in the gear boxes of each tracker.

Only drive motor heads, redundant, resist reactions as mechanical support . Only they require a strong foundation. This allows substantial savings in roof fixations, or foundation in solar farms .

Up to 100 trackers, model Galio E2S, can be driven by two geared motors. Impact resistant reactions only affects the heads of the motor ends and on every tracker forces are balanced, minimizing ground fixing needs. In each traction head there are two drive motors. Thus, each axis of rotation has a redundant motor assuring the functioning of the solar tracker with a motor failure . The system notifies the motor breakdown remotely, while maintaining the system functionality.

Trackers are nano technologically corrosion coated. This doubles the endurance in cloud chamber over galvanized treatment. This coating provides an excellent surface finish, incorporating the color desired by the developer ( PPA ). This technology reduces the corrosion cost by 75 % compared to galvanized, making mechanical adjustments after the treatment stage easier. The corrosion warranty is general for any country , unlike galvanized, increasing the bankability of PV projects made with these trackers.

On the ground, they can be micropiloted or welded to an UPN mesh strcture, achieving lower cost and a high rate of installation. This is a great advantage in countries with high costs of concrete installations or special regions ( Fukushima and Chernobyl) .